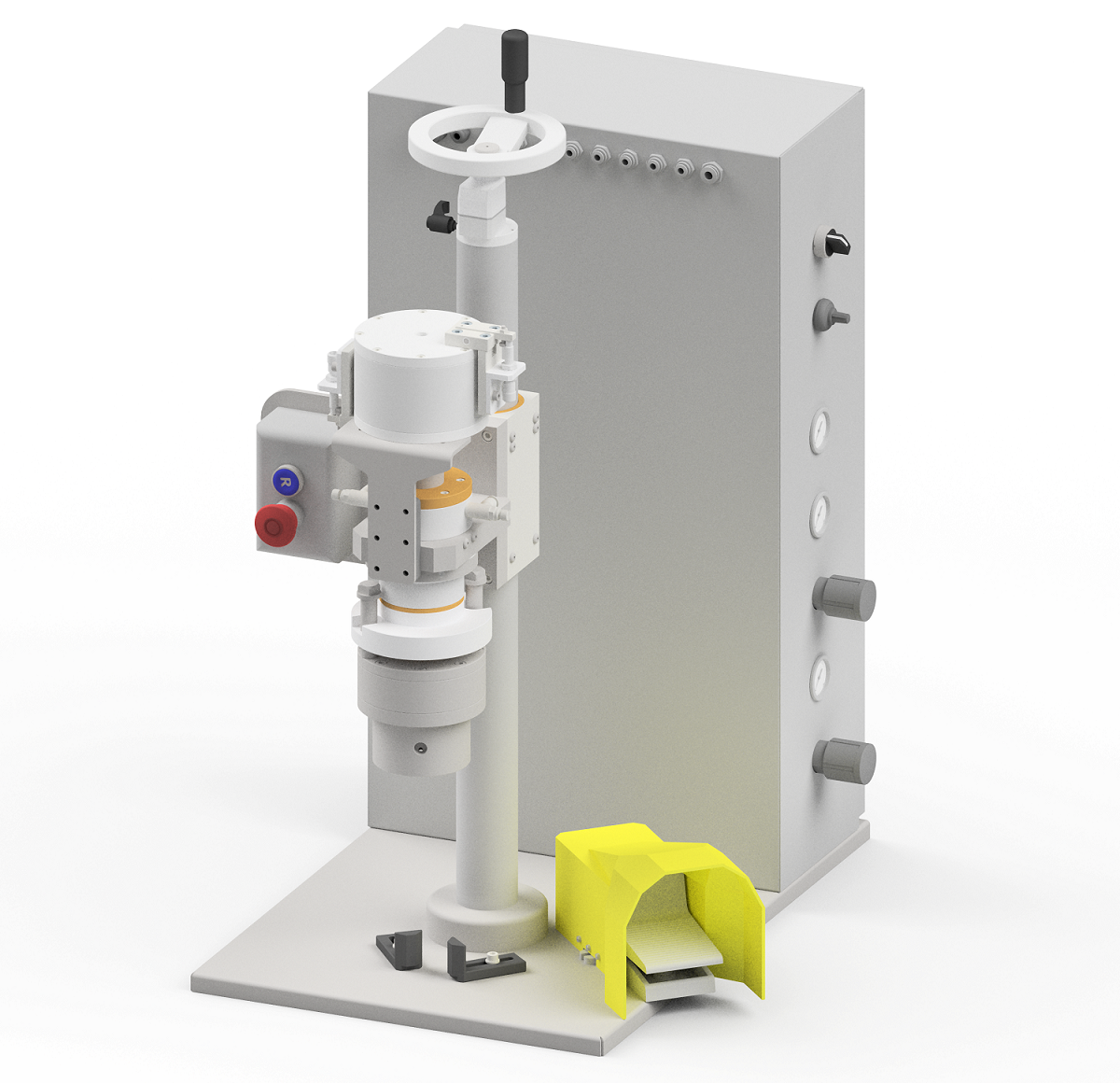

BAG ON VALVE (BOV)

SEMI-AUTOMATIC BOV CRIMPING MACHINE TYPE Z-2312

Semi-automatic BOV Crimping Machine Z-2312 is a device used for crimping Bag On Valves onto aerosol containers after pre-gassing them (UTC-filling) with compressed air or nitrogen.

- Optional version: BOV Crimping machine with pressure control system: Pressure control system is designed for controlling the pregasifying pressure (pressure of propellant outside the bag) – using specially designed testing head which injects specified dose of nitrogen inside the bag, measures output pressure and removes the injected nitrogen from the bag. NOTE! Adding pressure control system will increase the overall dimensions of the machine!

Working parameters

Operational parameters

Production capacity:

Up to 1000 pcs/h (16 containers/min) The maximum capacity is dependent on can size, work organization and operator’s experience

Containers diameter:

ø35 mm ÷ ø66 mm

Containers height:

40 mm ÷ 300 mm

Dimensions and mass

Width:

485 mm

Length:

595 mm

Height:

815 mm

Mass:

~ 92 kg

Supply

Type of supply:

Electric and pneumatic

Air supply pressure:

0.8 ÷ 1.0 MPa (8 ÷ 10 bar)

Air consumption:

6.9 litres / cycle

Air supply connection:

Pneumatic push-in fitting ø12 mm

Quality of compressed air:

4th class according to ISO 8573-1 for temperature range 15 ÷ 35°C

Supply voltage:

230V, 50Hz

Power:

130W